The wellness industry continues to experience unprecedented growth, with yoga studios, fitness centers, and retreat facilities seeking reliable suppliers for essential equipment. Among these necessities, yoga towels have emerged as a critical component that directly impacts client satisfaction and business reputation. When sourcing yoga towels in bulk quantities, understanding quality indicators, supplier capabilities, and market dynamics becomes essential for making informed purchasing decisions that align with both budget constraints and performance expectations.

High-quality yoga towels primarily utilize advanced microfiber technology that delivers superior moisture absorption compared to traditional cotton alternatives. The fiber density and weave pattern determine how effectively these towels manage perspiration during intense practice sessions. Premium yoga towels feature ultra-fine synthetic fibers measuring less than one denier in thickness, creating microscopic channels that rapidly wick moisture away from the skin surface while maintaining a dry grip-enhancing texture.

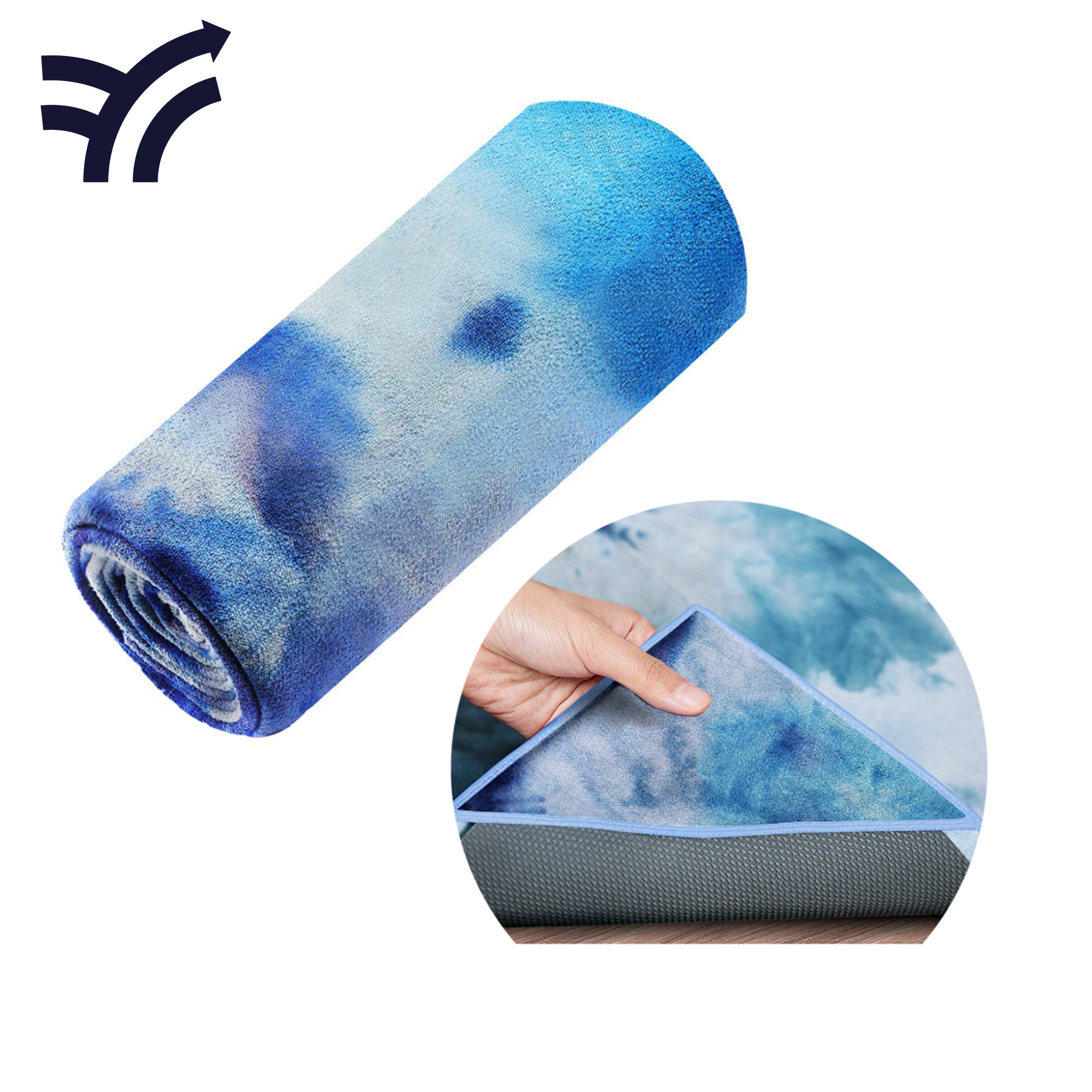

Manufacturing specifications for professional-grade yoga towels typically include fiber counts ranging from 200,000 to 400,000 fibers per square inch, directly correlating with absorption capacity and durability. The construction process involves specialized weaving techniques that create a dual-layer structure, with the top surface optimized for grip enhancement and the bottom layer designed for moisture distribution and mat adhesion. These technical considerations significantly impact the long-term performance and user satisfaction ratings of bulk-ordered inventory.

Commercial-grade yoga towels must withstand frequent washing cycles while maintaining their structural integrity and functional properties. Quality assessment involves examining reinforced edge construction, colorfast dye processes, and fabric resilience under repeated stress conditions. Superior yoga towels maintain their original dimensions and absorption capabilities even after hundreds of wash cycles, making them cost-effective investments for high-traffic fitness facilities.

Testing protocols for bulk orders should include evaluation of pilling resistance, color retention under various washing temperatures, and grip performance degradation over time. Manufacturers specializing in commercial yoga towels often provide detailed performance data including shrinkage rates, tensile strength measurements, and absorption capacity retention percentages that help buyers make informed decisions about long-term operational costs and replacement schedules.

Reputable suppliers of yoga towels maintain comprehensive certification portfolios that demonstrate adherence to international quality and safety standards. Essential certifications include OEKO-TEX Standard 100 for textile safety, ISO 9001 for quality management systems, and specific environmental compliance certifications that ensure responsible manufacturing practices. These credentials provide assurance that bulk orders will meet regulatory requirements and maintain consistent quality across large production runs.

Production facility audits and third-party quality assessments offer additional verification layers when evaluating potential suppliers. Leading manufacturers typically welcome facility inspections and provide detailed documentation of their quality control processes, raw material sourcing protocols, and finished product testing procedures. This transparency enables buyers to assess supplier capabilities and establish confidence in their ability to deliver consistent results for ongoing bulk order requirements.

Before committing to large-scale orders, requesting comprehensive sample collections allows for thorough evaluation of different yoga towel specifications and performance characteristics. Sample testing should include real-world usage scenarios, comparing absorption rates, grip enhancement properties, and user comfort across various environmental conditions and practice intensities. This hands-on evaluation process helps identify the most suitable products for specific facility requirements and client demographics.

Performance validation protocols should extend beyond basic functionality testing to include laundering trials, durability assessments, and user feedback collection. Establishing standardized testing criteria enables objective comparison between different suppliers and product lines, ensuring that bulk purchase decisions are based on measurable performance data rather than marketing claims or price considerations alone.

Bulk purchasing of yoga towels involves understanding complex pricing structures that vary based on order quantities, customization requirements, and delivery timelines. Most suppliers offer tiered pricing models with significant cost reductions available for orders exceeding specific quantity thresholds. Strategic procurement planning can leverage these volume discounts to achieve substantial cost savings while ensuring adequate inventory levels for operational continuity.

Negotiation strategies for yoga towels should focus on establishing long-term partnership agreements that provide price stability and priority production scheduling. Suppliers often offer additional value through extended payment terms, complimentary customization services, or bundled accessories when presented with committed purchasing agreements spanning multiple order cycles. These relationship-building approaches can result in total cost of ownership reductions that extend well beyond initial unit price considerations.

Effective inventory management for yoga towels requires balancing carrying costs against stockout risks and seasonal demand fluctuations. Analysis of usage patterns, replacement cycles, and peak demand periods helps optimize order timing and quantities to minimize total inventory investment while ensuring consistent product availability. Many facilities benefit from establishing automated reorder systems based on predetermined inventory thresholds and lead time requirements.

Seasonal considerations significantly impact both pricing and availability of yoga towels, with peak fitness industry seasons creating supply chain pressures that affect delivery timelines and costs. Strategic buyers often place advance orders during off-peak periods to secure favorable pricing and guaranteed delivery schedules for high-demand seasons. This forward-planning approach helps avoid supply shortages and premium pricing that commonly occur during peak procurement periods.

Custom branding on yoga towels provides valuable marketing opportunities while creating professional, cohesive facility aesthetics that enhance brand recognition and customer loyalty. Modern printing technologies enable high-resolution logo reproduction, custom color schemes, and detailed design elements that maintain clarity and vibrancy throughout extended use and laundering cycles. Quality customization requires understanding different printing methods, their durability characteristics, and compatibility with specific towel materials.

Design specification requirements for custom yoga towels include consideration of logo placement, size constraints, color matching capabilities, and minimum order quantities for customization services. Many suppliers offer digital mockup services that allow visualization of final products before production commitment, ensuring that branding elements meet expectations and align with overall facility design themes. These preview capabilities help prevent costly customization errors and ensure satisfaction with final results.

Color selection for bulk yoga towel orders involves balancing aesthetic preferences with practical considerations such as stain visibility, color retention properties, and maintenance requirements. Darker colors typically offer better stain concealment but may show lint and residue more readily, while lighter colors provide a clean, fresh appearance but require more frequent replacement due to visible wear patterns. Understanding these trade-offs helps optimize color choices for specific facility environments and usage patterns.

Coordinating yoga towel colors with existing facility décor and equipment creates cohesive visual environments that enhance the overall user experience and reinforce professional facility management standards. Many successful facilities develop signature color schemes that extend across all soft goods, creating memorable brand associations and differentiating their offerings from competitors. This strategic approach to color coordination can contribute to customer retention and positive word-of-mouth marketing effects.

Establishing comprehensive quality control protocols for incoming yoga towel shipments protects against defective products and ensures consistency with specified requirements. Inspection procedures should include random sampling protocols, dimensional verification, material composition testing, and functional performance evaluation. Clear acceptance criteria eliminate ambiguity during receiving processes and provide objective standards for supplier performance evaluation.

Documentation requirements for quality control processes include photographic evidence, measurement records, and performance test results that support warranty claims or supplier feedback when issues arise. Maintaining detailed inspection records enables trend analysis and supplier performance tracking that inform future purchasing decisions and contract negotiations. These systematic approaches to quality control minimize operational disruptions and protect investment in bulk inventory purchases.

Effective logistics coordination for bulk yoga towel deliveries involves planning for proper storage conditions, handling procedures, and distribution workflows that maintain product quality and facilitate efficient inventory management. Storage requirements include climate-controlled environments that prevent moisture accumulation, mold development, and odor absorption that can compromise product quality before use.

Distribution planning for yoga towels should accommodate facility layouts, staff workflows, and cleaning protocols that ensure hygienic handling and presentation to end users. Many facilities benefit from implementing first-in-first-out rotation systems that prevent prolonged storage and maintain consistent product freshness across inventory cycles. These operational considerations contribute to overall customer satisfaction and help maximize the return on bulk purchasing investments.

Most manufacturers require minimum orders ranging from 100 to 500 units for standard yoga towels, with custom-branded products typically requiring 200 to 1,000 pieces depending on the complexity of customization. Premium suppliers often offer flexibility for smaller initial orders with established customers, while factory-direct purchasing may require larger commitments but provide better pricing for facilities with high volume requirements.

Request detailed product samples that allow for comprehensive testing under actual usage conditions, including moisture absorption rates, grip enhancement properties, and comfort factors. Many suppliers provide technical specifications including absorption capacity measurements, grip coefficient ratings, and comparative performance data that enable objective evaluation of different product options before committing to bulk purchases.

Microfiber yoga towels typically offer superior absorption capacity, faster drying times, and better durability compared to cotton alternatives, making them more cost-effective for high-traffic commercial environments. Cotton options provide natural fiber benefits and softer texture but require more frequent replacement and longer drying periods, impacting operational costs and inventory turnover requirements for busy facilities.

Assess supplier credentials including manufacturing certifications, production capacity documentation, and client references from similar facilities or organizations. Request facility tours or virtual inspections when possible, and establish clear communication protocols for order tracking, quality issues, and delivery scheduling to ensure reliable ongoing supply chain performance that supports operational continuity and customer satisfaction goals.